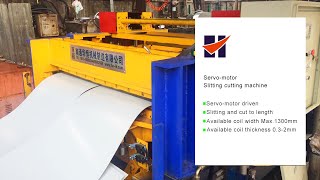

CTL1300X2 Servomotor Slitting Cutting Machine

Production flow:

Decoiling → Feeding → Slitting → Cutting to length → Out-putting

Main components:

|

No. |

Description |

Quantity |

|

1 |

Decoiler |

1 Nos |

|

2 |

Feeding, guiding, flattening, slitting and cutting unit |

1 Nos |

|

3 |

Control cabinet |

1 Nos |

|

4 |

Spares and tools |

1 Nos |

|

No. |

Description |

Specification |

|

|

Machine Model: CTL1300X2 |

|||

|

1 |

Performance |

Transmission type |

Servo motor + reducer + gear |

|

|

Servo motor power |

Approx 5kW |

|

|

Hydraulic station motor power |

Approx 3kW |

||

|

Productivity |

10-25m/min |

||

|

Length tolerance |

±1mm |

||

|

2 |

Main machine |

Flattening roller station |

Upper 4stations plus lower 5stations |

|

|

Roller material |

GCr15 bearing steel chromed |

|

|

Shaft material |

40Cr thermal refining |

||

|

Shaft diameter |

Approx 90mm |

||

|

Machine wall plate thickness |

Approx 16mm |

||

|

3 |

Slitting |

Slitting roller blade quantity |

3 Nos (Customize-able) |

|

|

Slitting width |

Manually adjustable |

|

|

Slitting roller blade material |

Cr12Mov |

||

|

4 |

Cutting |

Cutting width |

0-1300mm |

|

|

Cutting blade material |

Cr12Mov |

|

|

5 |

Control |

Production |

HMI PLC (Touchscreen display) |

|

|

Speed |

Servomotor control |

|

|

6 |

Decoiler |

Manual decoiler |

Manually expansion |

|

|

Loading capacity |

Max. 5tons |

|

|

Internal diameter of coil |

480mm-520mm |

||

|

Outer diameter of coil |

Max. 1000mm |

||

|

Width of coil |

Max. 1250mm |

||

|

Thickness of coil |

0.30-2.00mm |

||

|

Material of coil |

GI,PPGI,PPGL,G550 |

||

|

7 |

Electrics |

PLC |

Wuxi Xinje |

|

|

Servo-motor |

Wuxi Xinje |

|

|

Encoder |

Japan Omron |

||

|

HIM |

China Touchwin |

||

|

Contactor |

German Siemens |

||

|

Voltage regulator |

German Siemens |

||

|

Relay |

Japan Omron |

||

|

Limit switch |

China CNTD |

||